The CriticalWIP1, short for critical work in process, is just as the MaxWIP a production control logic (PCL) that restricts the WIP level over parts of or the complete production flow. The objects marking the entries (must be Operations) and the exit (must be a Buffer) of the controlled part of the production flow is referred to as the entry object(s) and exit object of the PCL. The CriticalWIP PCL controls the WIP level by restricting the entry of variants to the PCL controlled part of the production flow. Variants are allowed to enter when the inventory of the PCL exit object fall below a user specified CriticalWIP level. The CriticalWIP level is specified as a percentage of the capacity of the exit object of the PCL.

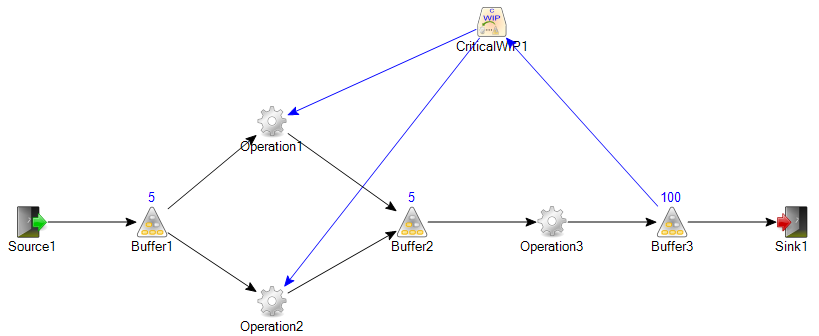

The CriticalWIP object is used by simply connecting it with flow objects in the model. A connection from the CriticalWIP object to a flow object marks an entry point of the CriticalWIP and vice versa a connection from a flow object to a CriticalWIP object marks an exit point of the CriticalWIP. There can be several entry objects but only one exit object of a CriticalWIP, see example below (Operation1/Operation2 - entries and Buffer3 - exit).

Note: The entries and exit of the CriticalWIP logic as well as the CriticalWIP object itself must be on the same level in the model, e.g. connections can't be made into a Component.

Note: Assembled parts are only counted as one unit.

Settings

The settings of the CriticalWIP are listed below along with a short description and possibly a link to a more detailed description about the setting.

|

Setting |

Description |

|

Name |

Sets the name of the object. |

|

Location |

Displays the location of the object. |

|

Percent limit |

Used to determine at what inventory level (CWIP level) of the exit object that variants should be allowed to enter the PCL controlled part of the production flow. The CriticalWIP level is calculated with this percentage and the capacity of the exit object according to the formula below. Range (0,100).

|

|

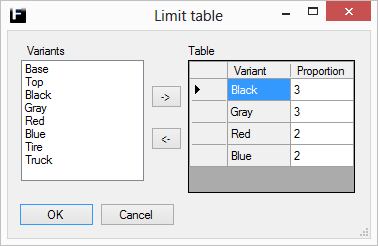

Limit table |

Used to devide the CriticalWIPlevel between variants. The variant capacities are calculated by dividing the CriticalWIPlevel among the different variants using a proportion figure, see image to the right. Given a CriticalWIPlevel of 100 (i.e. Percent limit = 100 % in the example above) and the proportions in the example to the right the variant inventory levels would be:

|

|

User attributes |

Lists all attributes that the user has added to the object. See User attributes for more details. |