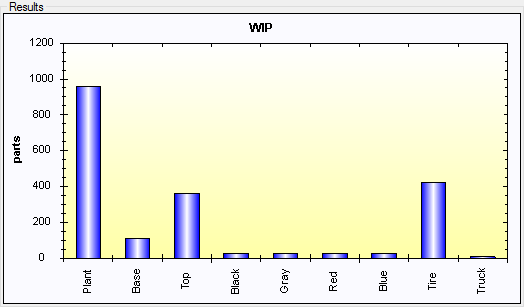

The output WIP (Work In Process) is displayed for the entire model and named Plant as well as for each individual variant in the image below. WIP takes up space, costs money (due to the capital investment made in the products) and introduces a risk for the variants/products being outdated, which are all reasons for keeping the WIP level at a minimum. On the other hand lowering the WIP level often also lowers the throughput.

Definition

WIP is the average amount of unfinished variants/products in the model over time. Variants/products contribute to the WIP level when situated on all objects but the Source and Sink objects.

Note: Variants/products assembled together on a Assembly station counts as one variant/product until they possibly are disassembled at a Disassembly station.

Result chart

The Results view displays all WIPs side by side in a barchart. Details about navigating these charts can be found here.