The Parallel Operation can process parts in a synchronized manner, i.e. in cycles. For example it can be used to model a machine with two spindles (a Double Spindle machine). To illustrate how this is done an example is given below.

Double Spindle Machine Example

A double spindle machine is common within industry mainly due to the fact that they are both smaller and cheaper than having to machines in parallel. However, they are not as flexible since they are only able to process identical parts simultaneously.

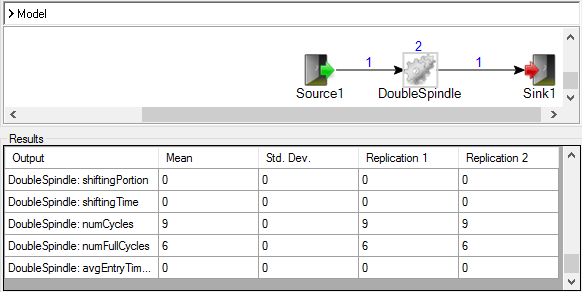

The example model to the right represents the simples possible model with a double spindle machine. It is simply a parallel machine with the following settings:

- NumOPs = 2 - Two spindles in the machine.

- Mixed processing = False - Avoid simultaneous processing of parts of different types.

- Synchronize entries = True - Enable cycle processing, i.e. parts are only allowed to enter at the same* time.

*: Actually during the specified Entry timeout from the entry of the first part in the cycle.- Entry timeout = 0 - Only allow parts of a new cycle to enter at the exact same time.

If set to something other than 0 it can delay the start of a new cycle in order to give an additional compatible part the chance to arrive.- Synchronize exits = True - Make sure all parts in current cycle are finished before they try to leave.

- Failure zone = True - Ensure that the entire machine fails if one of the internal operations fails.

In the example the machine is fed with two types of parts A and B, in the following sequence {A, A, A, B, B, A, A, A, B, B, ...}. This means that every third cycle will process a single A, i.e. one of the internal machines will be utilized less. This can be seen both in the Utilization-chart (smaller working portion) as well as more detailed on the Parallel Operation itself (Num Cycles and Num Full Cycles) in the figures to the right.